Collection: Products

-

![]()

![]()

Prometeo, the new Cryotek Eng system, was conceived to bring together all the instrumentation of a classic system in a single skid that can be easily transported and installed immediately by connecting it to existing lines.

In a single solution there are all the gas conditioning systems necessary for the production of technical, industrial and food mixtures.

Default Title

PROMETHEUS – Complete structure ready for use

PROMETHEUS – Complete structure ready for use

-

![]()

![]()

The flow regulator modelRFit is an instrument composed of a calibrated stem with gradual taper.

Default Title

Flow Regulator Mod.RF

Flow Regulator Mod.RF

-

![]()

![Pressure Reducer Mod. RBP]()

![]()

The model pressure reducerRBPit is a second stage reducer suitable for high flow rates.

It finds particular use in the laser and food sectors, in those applications in which a constant and important flow of gas is necessary to compensate for particularly demanding processes.

Default Title

Pressure Reducer Mod. RBP

Pressure Reducer Mod. RBP

-

![]()

![Pressure Reducer Mod. RP0]()

![]()

Second stage reducer for medium flow rates.

Thanks to the use of new construction techniques, the use of innovative materials and the use of self-regulating gas control systems, the system becomes reliable, flexible and simple to manage.

Available in different versions with or without pressure gauges.Default Title

Pressure Reducer Mod. RP0

Pressure Reducer Mod. RP0

-

![]()

![Pressure reducer mod. STAR & STAR2]()

![]()

The first stage pressure reducer modelSTAR2made from bar stock and its predecessor STAR made from mould, are suitable for use with a large number of technical gases and are built according to standardsEN ISO 2503.

Default Title

Pressure reducer mod. STAR & STAR2

Pressure reducer mod. STAR & STAR2

-

![]()

![Pressure reducer mod. VALVOPLAN II]()

![]()

The pressure reducer mod. Valvoplan II , an evolution of its historic predecessor, is particularly suitable where maximum constancy of the gas flow rate is required. It is one of the top products for practicality and functionality and improves the already known advantages of the previous version, namely the great precision and consistency of gas supply even when the pressure in the cylinder varies.

It is equipped with a large diaphragm and a high pressure valve, therefore the sensitivity of regulation guarantees absolute stability and maximum safety thanks to the characteristic overflow system, which intervenes if the pressure exceeds the set value by 0.6 bar predetermined.

The system can be created for all combustible and oxidising gases with the exception of Oxygen and Acetylene, and is available, on request, complete with one or two flow meters, standard or increased preheater, both preheater and flow meter.This instrument introduces some new and important aspects: the gas saving system, which allows a significant reduction in consumption, the integrated pre-heating system and the possibility of powering and regulating up to two welding machines simultaneously thanks to the double flow meter. All these solutions can be integrated into a single reducer, avoiding the need to combine different and expensive independent instruments.

Available in the version with flow meter, double flow meter, pre-heater, increased pre-heater, both accessories

Available with specific treatments for pure and food gases.Nobody / Nobody

Nobody / Standard

Nobody / Increased

Single / Nobody

Single / Standard

Single / Increased

Double / Nobody

Double / Standard

Double / Increased

Pressure reducer mod. VALVOPLAN II

Pressure reducer mod. VALVOPLAN II

-

![]()

![Pressure reducer for corrosive gases]()

![]()

This pressure reducer has been totally engineered and made of stainless steel for use with corrosive gases and for applications in which the construction materials become essential to ensure the resistance and durability of the instrument itself.

The adjustment of the output pressure is easily managed thanks to a nylon knob, the pair of pressure gauges allows direct control over the adjustment. The overpressure valve ensures safe working.

Available in different versions with or without pressure gauges.Default Title

Pressure reducer for corrosive gases

Pressure reducer for corrosive gases

-

![]()

![Roboflow Total Control di Cryotek Eng: sistema innovativo di miscelazione gas per precisione e flessibilità in varie applicazioni come saldatura, trattamenti termici, alimentare, oreficeria, elettronica e ricerca. Controllo totale dei costi di produzione.]()

![]()

Thanks to continuous research studies and many years of development and testing, our Roboflow Total Control is now ready and available.

Roboflow Total Control is the most innovative mixing system from Cryotek Eng, i.e. the perfect combination of flexibility, reliability and performance.

The new gas mixing system is an improvement of the previous Cryotek Eng electronic mixing system, a version designed to ensure the highest precision in all operational functions.

Ready to be configured for a wide range of gases, Roboflow Total Control is the most flexible and convenient automatic tool for managing and mixing gases.

The instrument allows you to use and control one or more gases supplied and therefore allows total control of production costs.

It is used in the most varied fields of application such as: welding, heat treatments, food, goldsmithing, clean rooms, advanced electronics and research. Sectors in which digital management of the entire process must also be added to the precision of the mixture strength.Default Title

Roboflow Total Control – Electronic Mixer

Roboflow Total Control – Electronic Mixer

-

![]()

![Automatic exchange decompression system]()

![]()

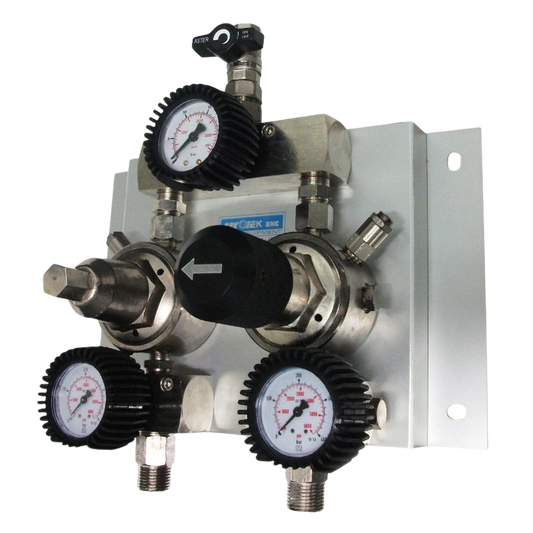

The semi-automatic exchange panel allows the connection of two incoming high pressure gas cylinders, regulating the pressure and introducing the gas into the low pressure line.

The conception of the exchange system allows for a system capable of automatically exchanging the incoming line, in the event of gas running out, with the secondary line already connected to the panel. Once the exchange has taken place, the operator who will replace the first gas source will rearm the automatic exchange and the operation is repeated.

Thanks to non-return valves and particular technical measures, the replacement of terminated sources can be carried out in complete safety.

Equipped with two input pressure gauges and one output pressure gauge for continuous pressure monitoring, overpressure valves placed directly on the reducer body and an output ball valve which allows simple disconnection from the line allowing for easy maintenance.Default Title

Automatic exchange decompression system

Automatic exchange decompression system

-

![]()

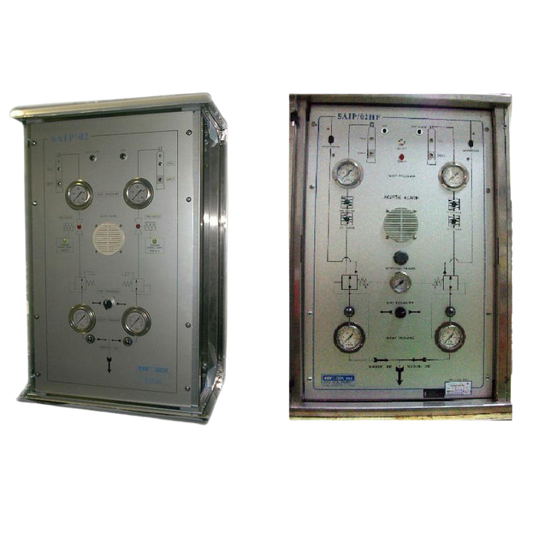

![D02HF Decompression System]() The D02 / D02HF decompression station is a complete gas reduction and control station that does not require any additional equipment.

The D02 / D02HF decompression station is a complete gas reduction and control station that does not require any additional equipment.![]()

The power plant is in fact already equipped with an inlet filtration system, first stage reducers and an integrated differential system capable of managing inlet pressures of up to 200 bar and outlet pressures of up to 10 bar. The electronic pressure transducers with which it is equipped are interfaced with alarm systems capable of warning when the cylinders are in reserve.

The control unit is completed with an automatic exchange system, capable of automatically switching to the full cylinder once the cylinder in process has entered reserve. The integrated alarms cannot be silenced except by replacing the cylinders and restoring the pressure initially set via the selector located on the front panel of the panel. The system is equipped with an interface for connection to an external electric alarm control unit.

The use of essential graphics and the panel-front installation of all the display systems make use and pressure calibration simple and intuitive.

Thanks to the operating principle of the automatic exchange system, it will no longer be necessary to stop production to change the cylinders.

The system is particularly suitable for Oil&Gas applications.Default Title

D02HF Decompression System

D02HF Decompression System

-

![]()

![EASYBORD Decompression System]() Single stage decompression system mod. Easyboard Star 2. The visible first stage decompression unit is equipped with two inlets with anti-transfer valves, thanks to which it is possible to replace the single source with the active panel. The system is completed by two pressure gauges, high and low pressure, and an outlet ball valve. Additionally, a pressure switch is available for remote control of the pressure in the high pressure chamber.

Single stage decompression system mod. Easyboard Star 2. The visible first stage decompression unit is equipped with two inlets with anti-transfer valves, thanks to which it is possible to replace the single source with the active panel. The system is completed by two pressure gauges, high and low pressure, and an outlet ball valve. Additionally, a pressure switch is available for remote control of the pressure in the high pressure chamber.![]()

The outlet pressure adjustment is easily adjustable thanks to a nylon knob, the pair of pressure gauges allows direct control over the adjustment. The overpressure valve ensures safe working.

Able to handle a wide range of gases: combustible, oxidising and inert. Thanks to the use of new construction techniques, the use of innovative materials and the use of self-regulating gas control systems, these instruments are reliable, flexible and simple to manage.

On request we produce versions for pure, hyperpure, medical and food gases.

Depending on the required output pressure, it can be equipped with a diaphragm (up to 10 bar) or with a piston system (up to 60 bar).

Available for mixes and with international bindings.Default Title

EASYBORD Decompression System

EASYBORD Decompression System

-

![]()

![Decompression System Mod. D118 OH]() The D118 OH decompression and distribution system offers the possibility of having in a single location:

The D118 OH decompression and distribution system offers the possibility of having in a single location:![]()

2 decompression groups and use of propane for heating with reel and 25 m hose.

2 decompression groups and use of oxygen-propane for cutting with 15 m twin hose reel.

In addition to the great practicality of combining 4 stations in a single structure, the D118 OH is equipped with a safety system which, in the event of an emergency, allows you to immediately shut off any flammable gas supply by pressing the button.

The entire structure is fixed to the ground using M12 anchor bolts and connected to the gas and air networks via UNI EN 1092-1 – PN40 flanges.

Hidden supports allow it to be moved and positioned easily.

The system is particularly suitable for Oil&Gas applications.Default Title

Decompression System Mod. D118 OH

Decompression System Mod. D118 OH

-

![]()

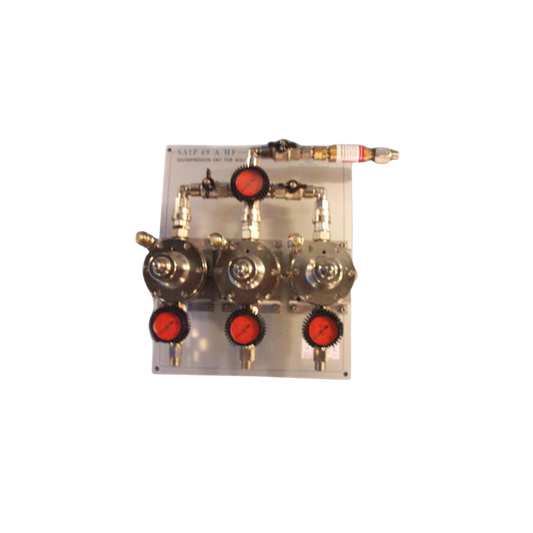

![Decompression System Mod. D49 A-HF]() The D49 A HF first stage acetylene decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting production.

The D49 A HF first stage acetylene decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting production.![]()

Each inlet is equipped with an upstream pressure gauge and a dedicated RBP reducer capable of providing up to 15 Nm3/h at 1.5 bar.

The inlet lines then converge into a single outlet equipped with a 1″ flame arrestor valve, a pressure gauge to monitor the outlet pressure and a main system supply valve. The system is particularly suited to Oil&Gas applications.Default Title

Decompression System Mod. D49 A-HF

Decompression System Mod. D49 A-HF

-

![]()

![Decompression System Mod. D49 O-HF]() The D49 HF first stage decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting the production.

The D49 HF first stage decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting the production.![]()

Each inlet is equipped with an upstream pressure gauge and a dedicated reducer capable of supplying up to 50 Nm3/h at 12 bar.

The inlet lines then converge into a single outlet equipped with a 1″ non-return flame valve, a pressure gauge to monitor the outlet pressure and a main system supply valve.

The system is particularly suitable for Oil&Gas applications.Default Title

Decompression System Mod. D49 O-HF

Decompression System Mod. D49 O-HF

-

![]()

![Propane Decompression System - Mod. D117]() The D117 propane decompression system is composed of a complete decompression unit inserted inside a specially designed steel container coated with a special paint that is particularly resistant to atmospheric agents.

The D117 propane decompression system is composed of a complete decompression unit inserted inside a specially designed steel container coated with a special paint that is particularly resistant to atmospheric agents.![]()

At the inlet we find the main valve and the filter, inside we find a 2nd stage RBP model reducer, capable of reaching a flow rate of 40 Nm3/h complete with adjustment screw accessible from the outside, pressure gauge and non-return flame valve.

Through the transparent pmma window it is possible to check the pressure gauge without the need to open the door.

At the outlet there is a reel equipped with 15 m of 8x15 mm orange rubber hose to which the torch for the actual

usage. The components of the D117 are also available individually:

D47 – Complete decompression unit.

Reel with 15 m of 8×15 mm rubber hose.

The system is particularly suitable for Oil & Gas applications.Default Title

Propane Decompression System - Mod. D117

Propane Decompression System - Mod. D117

-

![]()

![Miscelatore ad area variabile Cryotek Eng con due-quattro miscelatori autonomi, valvole micrometriche per taratura precisa e controllo del flusso.]()

![]()

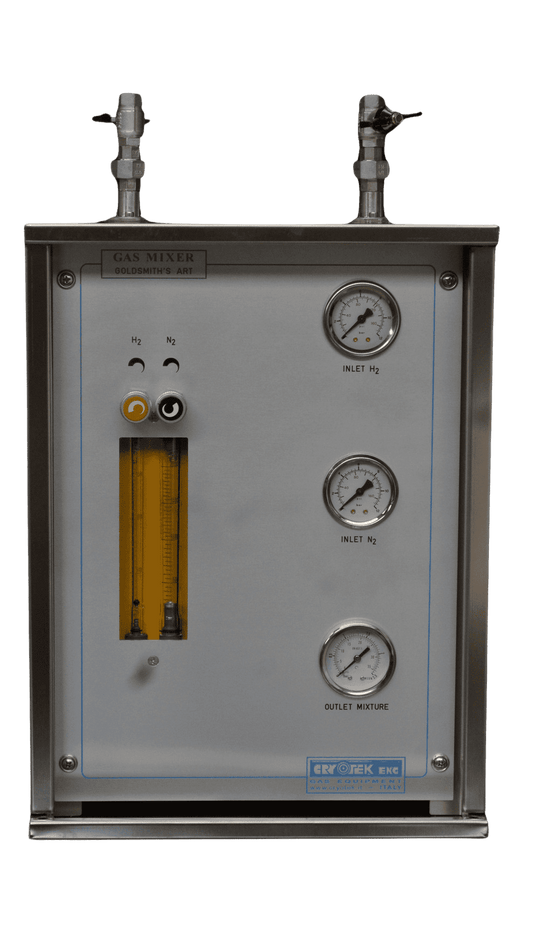

The Cryotek Eng variable area mixer is able to offer from two to four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the organization of the process throughout the production.

It allows you to set up to four mixtures, via a series of micrometric valves, which ensure flow calibration on each individual line, guaranteeing a mixture with a defined and accurate title.

This instrument offers the operator the possibility of having direct control over the strength of the mixture produced and , through a flow control system, also over the stability of the output mixture.

* Available with integrated alarm, blanketing and/or line blocking systems.Default Title

Variable area mixing system Mod. IV gold sector

Variable area mixing system Mod. IV gold sector

Contact us for information

DISCOVER OTHER PRODUCT CATEGORIES

-

![]()

Explore our wide range of accessories designed to optimize your gas distribution system and ensure the safety and efficiency of your working environment.

From universal connection kits that solve international connection challenges by ensuring operational safety and efficient production times, to rapid gas control and interception units that ensure safe and reliable management of plants.

Our RF flow regulators offer precision and adaptability in every situation, allowing precise adjustments of gas flows even in limited spaces.

Our double-acting valves, built to offer reliable pressure control in both overpressure and depression, ensuring flexibility and safety in every application.Accessories

-

Map-Check from Cryotek is a battery-operated food analyzer designed to check sealed packages according to the MAP method.

![]()

Available in two models, one for oxygen analysis and the other for oxygen, carbon dioxide and, on request, nitrogen .

With fast response times and low gas consumption, it offers reliability and precision.

Equipped with a large backlit display and integrated software with alarms and data logger for traceability.

Complete with accessories and wireless operation, it is the ideal option for precise, portable measurements in food production environments.Analyzers

-

![]()

Discover our complete range of decompression and gas control systems.

From semi-automatic exchange panels to complete decompression units, we offer reliable solutions for the management of inlet and outlet pressures.

Equipped with pressure gauges and safety valves, our systems ensure constant monitoring and safe operation.

Choose quality and reliability for your industrial needs with our decompression products.Decompression systems

-

![]()

Cryotek flow meters allow precise and reliable measurement of the flow or flow rate of gases, mixtures and liquids in any industrial context and can be used for different flow rates.

They are made of borosilicate glass to offer superior precision to the best flow meters around and optimal resistance in different contexts.

Flexible mounting modes provide maximum versatility to meet various flow measurement needs. Discover the difference with our flow meters today!

Flowmeters

-

Discover the hydrogen and oxygen production system designed for ships and shipyards, the result of the collaboration between PIEL and Cryotek Eng.

![]()

With a production capacity of up to 36,000 L/H, this system uses the electrolysis of demineralized water to generate pure gases.

Get significant benefits, such as saving on gas supply costs and reducing the space occupied by cylinders.

Reliable and secure , the system is available in centralized and mobile versions, with additional options on request.Generators

-

![]()

Our mixers are designed to meet the gas mixing needs of different industrial processes, ensuring precise control of the gas flow on each individual line.

With the ability to set up to four mixes, each mixer offers accurate mix strength adjustment, making them suitable for a wide range of gases and applications.

Made with high-quality materials and advanced technologies , our mixers offer reliable and long-lasting performance .

Equipped with integrated alarm and control systems, they guarantee maximum safety and control during the mixing process.

Discover the difference with our mixers today and get reliable, versatile performance for your industrial and food needs!Mixers

-

Discover our gas preheating systems, designed to offer superior performance and ensure reliability.

![]()

Thanks to our innovative heat exchange system, we ensure preheating values higher than 200% compared to traditional solutions.

Simple to install and control, our devices are ideal for treating pure gases and are also available for food use.

Choose quality and efficiency for your industrial needs.Pre-heating systems

-

![]()

Pressure reducers offer precise regulation of the gas flow, ensuring a constant and reliable flow rate.

They are easy to install and maintain over time, thanks to the high quality materials.Pressure reducers

-

Our automatic fire prevention system offers a practical and reliable solution to protect electrical panels and entire environments from fires.

![]()

Based on a special tube that activates automatically, it extinguishes the fire as it arises, ensuring safety without the need for electrical power.

Furthermore, the Quasar System offers tailor-made protection for systems, detecting and managing gas leaks effectively and compliant with international regulations.

Trust our technology to carry out any operation in maximum safety.Security systems

-

Explore our collection of advanced systems designed to ensure safety and efficiency in your facilities.

![]()

Prometeo, the new Cryotek Eng system, brings together all the instrumentation of a system in a single skid that can be transported and installed immediately.

Thanks to the perfect synchronization of the systems, you obtain incredible precision in the production of mixtures and total reliability in dispensing.

Furthermore, discover Quasar, the security system tailored for your system. With advanced sensors and gas interception panels, Quasar offers complete protection, ensuring operator safety and compliance with international regulations. Make yourself at the forefront of the industry with Prometheus and Quasar.

Special systems and installations