Collection: Products

-

![]()

![]()

Line mixing system patented and engineered by Cryotek Eng, a device suitable for applications in particularly demanding manufacturing processes, where it is essential to have an instrument capable of producing mixtures in percentages from 0 to 100% on each fluid.

Thanks to the use of highly reliable materials and an innovative construction concept, the instrument is able to cope with the most demanding situations, with precision and consistency.Default Title

Line mixing system

Line mixing system

-

![]()

![]()

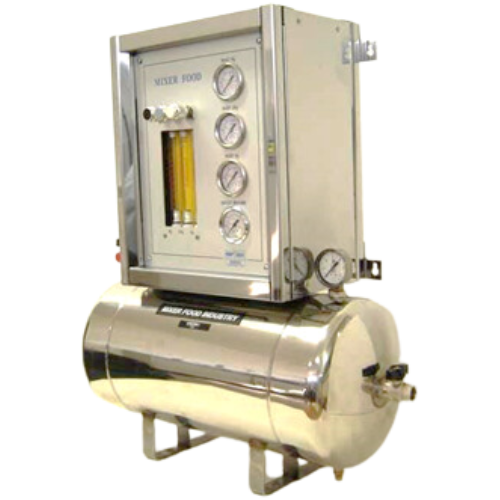

Compact mixing system, suitable for small flow rates and suitable for the goldsmith, industrial, chemical and food sectors.

The maximum flow regulation is entrusted to direct reading analog systems, based on the Pitot system designed, built and calibrated in our workshops since 1960.

The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.

The pressure regulators located inside the instrument are directly spring operated. If necessary, one-way valves can be supplied.

The device is housed inside a completely sealed stainless steel case, to avoid tampering by unauthorized personnel.

Thanks to its characteristics, the equipment is the result of an excellent combination of cost-effectiveness and product functionality.

Available with specific treatments for pure and food gasesDefault Title

Mixing System Mod. EASY MIXER

Mixing System Mod. EASY MIXER

-

![]()

![GoldMixer di Cryotek Eng, miscelatore in alluminio leggero e resistente, con flussimetri precisi, sinottico personalizzabile e controllo continuo della miscela.]()

![]()

Cryotek Eng, to respond to the growing needs of the goldsmith sector, has studied a new line of mixing systems. The GoldMixer System is an easy-to-install mixer with the advantage of adapting to every production process.

Assembled inside a small frame and made entirely of aluminium, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out thanks to borosilicate glass flowmeters , equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.

The aluminum front synoptic allows for intuitive and easy reading; capable of resisting wear, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies. The synoptic machined in aluminium, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

Absolute precision and high quality are guaranteed by the use of the most advanced technologies.

Default Title

Mixing system MOD. GoldMixer

Mixing system MOD. GoldMixer

-

![]()

![Miscelatore binario Cryotek Eng in acciaio inox, con flussimetri precisi, sinottico personalizzabile, e vari sistemi di sicurezza integrati.]()

![]()

The binary* food mixer produced by us is entirely adaptable to any mixture and gas necessary for the process.

Assembled inside a small frame, made entirely of stainless steel, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters, equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.**

The incoming lines are complete with a 60μ filtration system, balanced control piloted pressure reducing valves and one-way valves designed to avoid any pollution of the lines. A pilot reducer complete with analogue display placed on the front allows immediate and precise setting of the pressure of the outlet mixture.

The aluminum front synoptic allows for intuitive and easy reading; capable of resisting deterioration, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies. The synoptic machined in aluminum, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

* Possibility of ternary version.

**Optional insertion of remote end-of-gas alarms, acoustic, luminous or direct to PLC.

Available with different integrated accessories, including end-of-gas alarm systems, line blocking systems, detection systems, blanketing systems.Default Title

Mixing System Mod. IVA – Food Sector

Mixing System Mod. IVA – Food Sector

-

![]()

![Miscelatore binario/ternario per alimenti di Cryotek Eng, leggero e resistente, con flussimetri e sinottico personalizzabile.]()

![]()

The binary mixer* produced by us to meet the growing needs of the food industry has the advantage of adapting to every production process.

- Assembled inside a small frame, it is extremely light and resistant to all environmental conditions.

- The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters , equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

- Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.**

- The incoming lines are complete with a 60μ filtration system, balanced control piloted pressure reducing valves and one-way valves designed to avoid any pollution of the lines.

- A pilot reducer complete with analogue display placed on the front allows immediate and precise setting of the pressure of the outlet mixture.

- The front synoptic, available in both aluminum and plexiglass, allows for intuitive and easy reading; capable of resisting deterioration, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies.

- The synoptic machined in aluminum, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

* Possibility of ternary version.

**Optional insertion of remote end-of-gas alarms, acoustic, luminous or direct to PLC.Default Title

Mixing System Mod. IVA/N – Food Sector

Mixing System Mod. IVA/N – Food Sector

-

![]()

![Miscelatore mod. M04D di Cryotek Eng: quattro miscelatori autonomi in un unico telaio, controllo diretto del titolo e stabilità della miscela, segnali di pressione digitali e analizzatori integrati. Adatto per Oil & Gas.]()

![]()

The mixer mod. M04D is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization throughout the entire production.

It has the possibility of setting up to four mixtures through a series of micrometric valves which will perform the task of calibrating the flow on each individual line, thus generating a mixture with an accurately defined title.

The user has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system with visual alarm, the possibility of also having control over the stability of the outgoing mixture.

The system is equipped with digital input pressure signals to control the pressures and levels of gas autonomy in the racks and calibrated sockets designed to guarantee correct homogenization of the gas flows which allow the direct analysis of the individual mixtures with special analysers.

Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil & Gas applications.*Available in the version with integrated analysis and blocking system

Default Title

Mixing System Mod. M04D

Mixing System Mod. M04D

-

![]()

![Miscelatore M04S di Cryotek Eng: quattro miscelatori autonomi in un unico telaio, impostazione precisa delle miscele tramite valvole micrometriche, controllo diretto del titolo e stabilità della miscela. Lettura delle portate con sistema analogico Pitot. Adatto per applicazioni Oil & Gas.]()

![]()

Thanks to new construction techniques, the use of innovative materials and the use of gas control systems, the system becomes reliable, flexible and simple to manage.

The possible advantage is evident.

The M04S mixer is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization throughout the entire production. It has the possibility of setting up to four mixtures through a series of micrometric valves which will perform the task of calibrating the flow on each individual line, thus generating a mixture with an accurately defined title.

The reading of the flow rates will take place with direct reading analogue systems, based on the Pitot system. Designed, built and calibrated specifically for welding systems with large productions. The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.

Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M04S

Mixing System Mod. M04S

-

![]()

![M101S S di Cryotek Eng: quattro miscelatori autonomi in un unico telaio, sistemi di preriscaldo incorporati, valvole di sovrappressione settabili, lettura delle portate con sistema analogico Pitot. Adatto per applicazioni Oil & Gas.]()

![]()

The M101S S is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization with the possibility of setting up to four mixtures.

Complete with built-in preheating systems for each single line, 30°C thermostats, exclusion buttons, settable overpressure valves, reading socket for each single line and illuminated panel to allow viewing in low light.

The reading of the flow rates will take place with direct reading analogue systems, based on the Pitot system, designed, built and calibrated specifically for welding systems with large productions.

The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M101S

Mixing System Mod. M101S

-

![]()

![Sistema binario di miscelazione per saldatura: 2 vie separate, impostazione individuale del titolo e della pressione, condizionamento termico integrato, telaio in acciaio inox marino con sportello apribile. Adatto per Oil & Gas.]()

![]()

Binary mixing system for welding, with 2 separate mix delivery ways. Thanks to the total separation of the 2 lines, each mixture can be individually set in terms of strength and pressure, acting on the relevant flow meters and pressure reducers. The system is completed with integrated thermal conditioning and increased gas preheating systems, so as to allow its use at extremely low temperatures.

The entire system is placed inside a marine stainless steel frame equipped with an opening door and inspection window.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M20 ARTIC

Mixing System Mod. M20 ARTIC

-

![]()

![Sistema binario di miscelazione per saldatura: 2 vie separate, impostazione individuale del titolo e della pressione, condizionamento termico integrato, telaio in acciaio inox marino con sportello apribile. Adatto per Oil & Gas.]() Binary mixing system for welding, with 2 separate mix delivery ways.

Binary mixing system for welding, with 2 separate mix delivery ways.![]()

Thanks to the total separation of the 2 lines, each mixture can be individually set in terms of strength and pressure.

The M20 Total Vision mixing system also allows continuous control of the mixture, thanks to an integrated synoptic analysis system.

The digital flow meters placed downstream of the flow meters are capable, like the analyzer, of providing a remotely controllable and recordable signal of the flow rate and quantity values of the individual gases.

The entire system is placed inside a marine stainless steel frame equipped with an opening door and inspection window.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M20 Total Vision

Mixing System Mod. M20 Total Vision

-

![]()

![Miscelatore binario/ternario alimentare di nostra produzione, adattabile a varie miscele e gas. Telaio in acciaio inox, flussimetri calibrati, possibilità di impostare 3-10 miscele con titoli personalizzabili. Semplice reimpostazione in loco, riduzione degli errori. Accessori disponibili: allarmi, sistemi di blocco, rilevazione, polmonazione.]()

![]()

The binary or ternary food mixer produced by us is entirely adaptable to any mixture and gas necessary for the process. Assembled inside a small frame, made entirely of stainless steel, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters, equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.The peculiarity of this tool is that it can have from 3 to 10 pre-set blends with titles that can be customized and reset in a simple and intuitive way directly on site by the customer. In this way the end customer is guaranteed:

• A high-performance product in terms of applications (with the same tool it is possible to package different types of products with different mixtures)

• Greater protection of know-how and set blends.

• An absolute reduction in error when changing the mixture, as the mixture is no longer adjusted through the micrometric valves but by simply moving the knob.

Available with different integrated accessories, including end-of-gas alarm systems, line blocking systems, detection systems, blanketing systems.Default Title

MIXING SYSTEM FOR PRESET MIXTURES

MIXING SYSTEM FOR PRESET MIXTURES

-

![]()

![F19D measuring system]()

![]()

The F19D digital flow meter is a practical digital measurement tool thanks to which it is possible to measure the flow of gases and mixtures exiting the welding torch.

It is able to precisely measure gases, such as: Air, Nitrogen, Argon, Carbon Dioxide

It also allows the measurement of mixtures of Argon and Carbon Dioxide with different percentages:

Ar 80% – CO2 20%

Ar 70% – CO2 30%

Ar 60% – CO2 40%

Ar 92% – CO2 8%

Ar 90% – CO2 10%The instrument is equipped with a digital display with a reading precision of one decimal place.

The 3000 mA lithium battery power supply makes it easily transportable without any type of impediment; thanks to the included battery charger you can always have a product charged and ready for use.Default Title

F19D measuring system

F19D measuring system

-

![]()

![F19S measurement system]()

![]()

Analog instrument for controlling and measuring flow and pressure coming out of the torch. This product is designed not to require any external electrical power supply and can also be used by non-specialised personnel thanks to its intuitive and immediate functionality and versatility.

The pressure and flow rate reading is carried out using a special switch as needed.

The internal flowmeter is made of borosilicate glass hot calibrated in our specialized workshops.Default Title

F19S measurement system

F19S measurement system

-

![]()

![P16 L dry preheating system]()

![]()

Dry preheating system suitable for all types of anhydrous gases.

The instrument is characterized by its simplicity of installation.

Thanks to the innovative heat exchange system, it was possible to obtain higher preheating values, with the same power, than those currently in use.

The system is equipped with a potentiometer to be able to adjust the desired preheating value and a thermometer to be able to keep the gas temperature under control.

Furthermore, the pre-heater is equipped with two indicator lights which signal the operating status of the appliance, while the green indicator light indicates whether the heating phase is in progress.

The preheater is made in compliance with the ATEX reference regulations in the explosion-proof field and is CESI certified n° EX-99.E.067.

The total absence of welding, synonymous with perfect leakage resistance, makes the instrument suitable for any type of application.Default Title

P16 L dry preheating system

P16 L dry preheating system

-

![]()

![P96 cylinder preheating system]()

![]()

The P96 Artic cylinder preheating system has been specifically developed for use in environments with extremely low temperatures. It consists of a control unit capable of managing and controlling two special tyrewarmers (ATEX II 3G), with carbon fiber resistors, additional rock wool insulation and external aramid fabric with silicone surface treatment.

The tyrewarmers are specifically designed for operation in extremely cold environments, thus allowing the heating of gas cylinders even in extreme climates.

This system, composed as follows, allows the controlled heating of a maximum of two cylinders, allowing correct gasification inside them and therefore offering the possibility of correctly using the gas necessary for welding.Default Title

P96 cylinder preheating system

P96 cylinder preheating system

-

![]()

![Quasar system]()

![]()

Cryotek Eng, with a view to complying with current international regulations, has designed, patented and created some of the most efficient safety systems for plants.

For us, safety is not understood as a set of equipment but as a real concept that preserves the working environment and operators.

Precisely for this purpose, the Quasar System was created over several years of study and testing.

The Quasar System is a security system tailor-made for the reference plant and based on a comparison with the highly trained personnel of the plant.

STUDIES AT THE BASIS OF THE DESIGN:

– Study and analysis of the critical issues and risks relating to the different types of gas

– Study and analysis of the critical issues and risks relating to the system

– Identification of all possible risk areas and subdivision according to the different risk levels of the systems

QUASAR:

The heart of QUASAR is a centralized analysis system, capable of detecting any gas leaks in the environment, with sensors placed inside the protection jacket, to identify exactly where the leak is and intervene. Based on the extent of the leak, the system is able to detect three alarm thresholds, each of which is followed by different types of alarms and actions, from an acoustic and audible alarm to warn the line or station operators, to a remote shutdown of the entire system and purging in the event of more serious leaks. The system is also completed with gas interception panels, equipped with pressure detection, gas sampling and purging systems, capable of isolating a single section of the pipe, to allow operators to identify gas leaks without causing a plant stoppage.

WHY CHOOSE THE QUASAR SYSTEM:

The Quasar System would allow the requesting company and its managers basically 3 advantages:

1. Propose itself as an innovative company within the sector by using and having expertise regarding one of the most innovative security systems of recent years

2. Completely discharge the responsibilities related to the conveyance and use of dangerous gases, since the system is in itself a guarantee and created to protect the operators and those responsible for the plant

3. Preserve your operational staff and make them at the forefront of the sector.Default Title

Quasar system

Quasar system

Contact us for information

DISCOVER OTHER PRODUCT CATEGORIES

-

![]()

Explore our wide range of accessories designed to optimize your gas distribution system and ensure the safety and efficiency of your working environment.

From universal connection kits that solve international connection challenges by ensuring operational safety and efficient production times, to rapid gas control and interception units that ensure safe and reliable management of plants.

Our RF flow regulators offer precision and adaptability in every situation, allowing precise adjustments of gas flows even in limited spaces.

Our double-acting valves, built to offer reliable pressure control in both overpressure and depression, ensuring flexibility and safety in every application.Accessories

-

Map-Check from Cryotek is a battery-operated food analyzer designed to check sealed packages according to the MAP method.

![]()

Available in two models, one for oxygen analysis and the other for oxygen, carbon dioxide and, on request, nitrogen .

With fast response times and low gas consumption, it offers reliability and precision.

Equipped with a large backlit display and integrated software with alarms and data logger for traceability.

Complete with accessories and wireless operation, it is the ideal option for precise, portable measurements in food production environments.Analyzers

-

![]()

Discover our complete range of decompression and gas control systems.

From semi-automatic exchange panels to complete decompression units, we offer reliable solutions for the management of inlet and outlet pressures.

Equipped with pressure gauges and safety valves, our systems ensure constant monitoring and safe operation.

Choose quality and reliability for your industrial needs with our decompression products.Decompression systems

-

![]()

Cryotek flow meters allow precise and reliable measurement of the flow or flow rate of gases, mixtures and liquids in any industrial context and can be used for different flow rates.

They are made of borosilicate glass to offer superior precision to the best flow meters around and optimal resistance in different contexts.

Flexible mounting modes provide maximum versatility to meet various flow measurement needs. Discover the difference with our flow meters today!

Flowmeters

-

Discover the hydrogen and oxygen production system designed for ships and shipyards, the result of the collaboration between PIEL and Cryotek Eng.

![]()

With a production capacity of up to 36,000 L/H, this system uses the electrolysis of demineralized water to generate pure gases.

Get significant benefits, such as saving on gas supply costs and reducing the space occupied by cylinders.

Reliable and secure , the system is available in centralized and mobile versions, with additional options on request.Generators

-

![]()

Our mixers are designed to meet the gas mixing needs of different industrial processes, ensuring precise control of the gas flow on each individual line.

With the ability to set up to four mixes, each mixer offers accurate mix strength adjustment, making them suitable for a wide range of gases and applications.

Made with high-quality materials and advanced technologies , our mixers offer reliable and long-lasting performance .

Equipped with integrated alarm and control systems, they guarantee maximum safety and control during the mixing process.

Discover the difference with our mixers today and get reliable, versatile performance for your industrial and food needs!Mixers

-

Discover our gas preheating systems, designed to offer superior performance and ensure reliability.

![]()

Thanks to our innovative heat exchange system, we ensure preheating values higher than 200% compared to traditional solutions.

Simple to install and control, our devices are ideal for treating pure gases and are also available for food use.

Choose quality and efficiency for your industrial needs.Pre-heating systems

-

![]()

Pressure reducers offer precise regulation of the gas flow, ensuring a constant and reliable flow rate.

They are easy to install and maintain over time, thanks to the high quality materials.Pressure reducers

-

Our automatic fire prevention system offers a practical and reliable solution to protect electrical panels and entire environments from fires.

![]()

Based on a special tube that activates automatically, it extinguishes the fire as it arises, ensuring safety without the need for electrical power.

Furthermore, the Quasar System offers tailor-made protection for systems, detecting and managing gas leaks effectively and compliant with international regulations.

Trust our technology to carry out any operation in maximum safety.Security systems

-

Explore our collection of advanced systems designed to ensure safety and efficiency in your facilities.

![]()

Prometeo, the new Cryotek Eng system, brings together all the instrumentation of a system in a single skid that can be transported and installed immediately.

Thanks to the perfect synchronization of the systems, you obtain incredible precision in the production of mixtures and total reliability in dispensing.

Furthermore, discover Quasar, the security system tailored for your system. With advanced sensors and gas interception panels, Quasar offers complete protection, ensuring operator safety and compliance with international regulations. Make yourself at the forefront of the industry with Prometheus and Quasar.

Special systems and installations