FOOD INDUSTRY

Cryotek Eng has been a world leader in the production and marketing of technologies for the food sector for over 50 years.

We are able to develop, produce and install the most advanced technologies, carrying out feasibility studies , projects , specific consultancy and the creation of entire systems dedicated to this sector, respecting current regulations.

Cryotek Eng can respond to any customer request, offering technologically advanced opportunities useful for the expected results of our buyers.

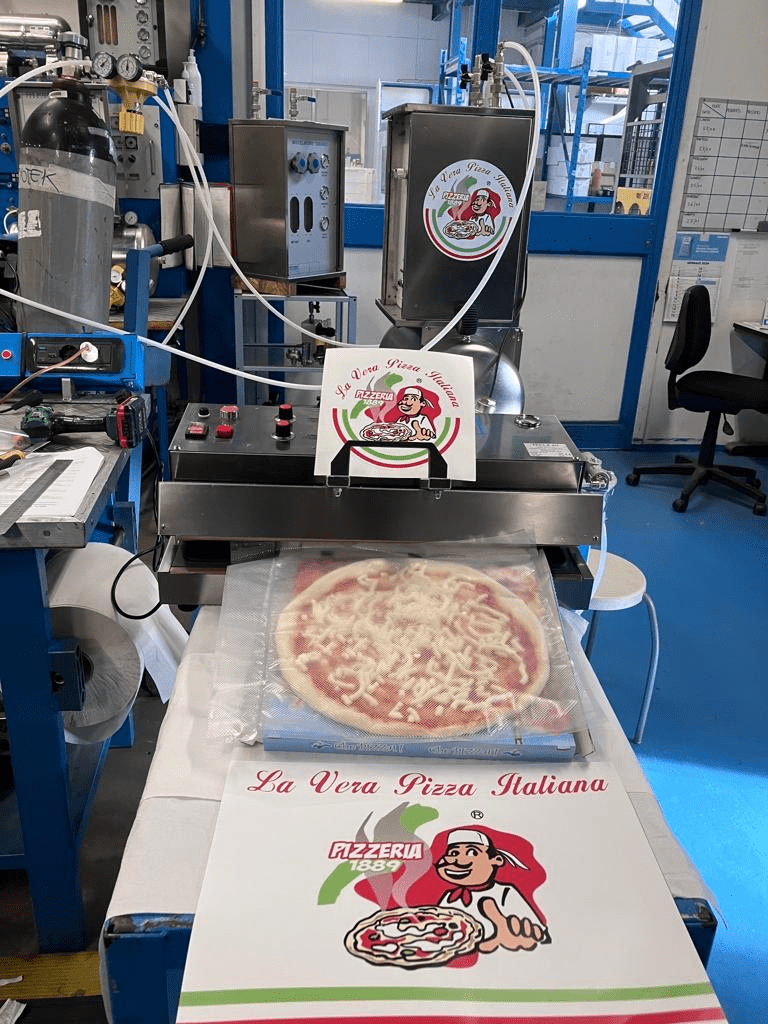

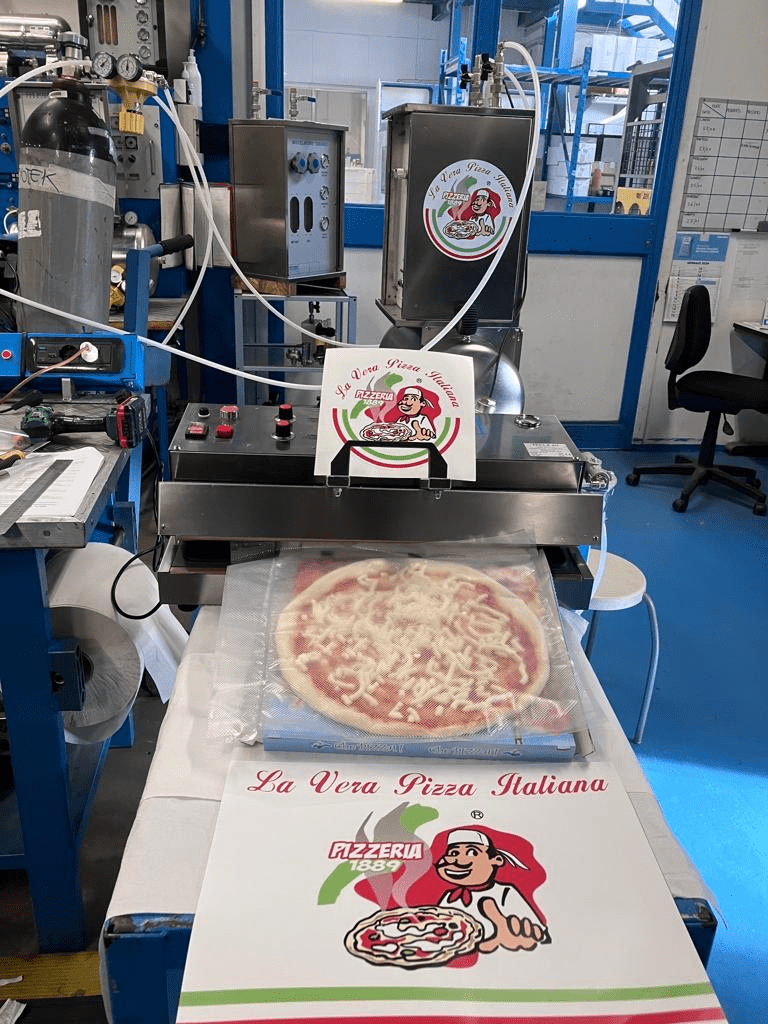

PIZZERIA 1889

news in the food sector

We have recently developed a system to increase and develop the sales potential of pizzerias that meet some essential quality requirements without any investment cost on your part.

significant increase in turnover

The pizzerias that have joined our project to date have seen a notable increase in turnover thanks to our know-how. This project will not interfere in any way with your current production and philosophy. As partners, you will be included in our national advertising promotion, which refers to "Pizzeria 1889".

contact us and receive the details

The project is currently strictly confidential. Therefore, if interested, we await your quick response, to both evaluate the possibility of starting a profitable collaboration.

You can contact the Cav project manager. Biagio Grassi by calling 335-5446200 or by sending an email to grassib@cryotek.it .

MAP TECHNOLOGY

Raising the standards of our products in order to guarantee food freshness without compromising their organoleptic qualities is a priority for Cryotek Eng.

Our range of variable area gas mixing systems, approved by the prestigious MAP Consortium , naturally extends the shelf life of food, keeping its flavor and quality intact .

MAP technology , with its protected air packaging, represents a fundamental pillar to guarantee optimal preservation of fresh foods.

Thanks to our cutting-edge and certified equipment, we are committed to providing reliable and quality solutions in the food sector, reducing food waste as much as possible and maintaining constant quality over time.

Contact us

products and services

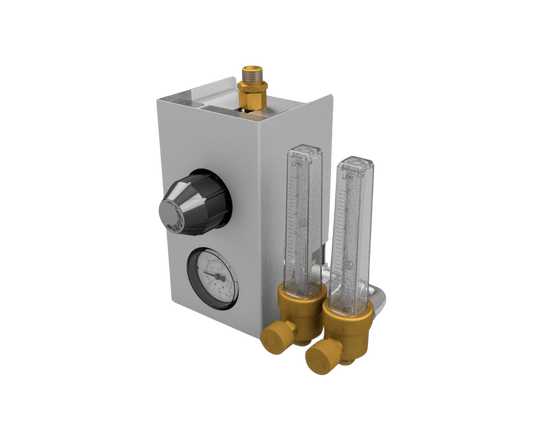

Gas Mixing Systems: Gas Mixer Model VAT/No

- Key solution for creating stable and economical mixes in the food sector.

- It allows rapid variation of the mixture strength to personalize the "recipes" and improve the customer's know-how.

- It guarantees the precision of the mixture title, avoiding stratification of the gases in the cylinder.

- Minimizes costs in purchasing primary gases, with rapid amortization of the cost incurred.

Second stage pressure reducers

They ensure adequate pressure in food gas distribution systems, guaranteeing the safety and quality of the final product.

-

![]()

![]()

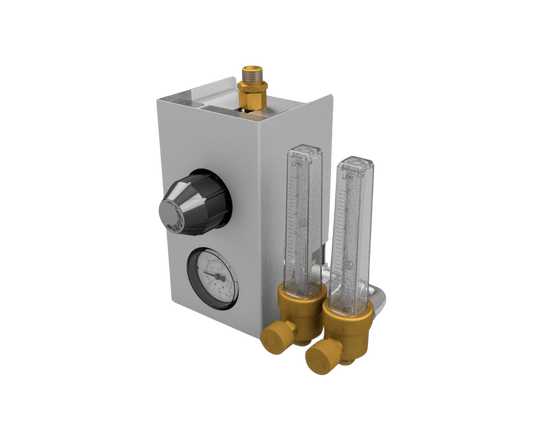

The pressure reducer mod. Valvoplan II , an evolution of its historic predecessor, is particularly suitable where maximum constancy of the gas flow rate is required. It is one of the top products for practicality and functionality and improves the already known advantages of the previous version, namely the great precision and consistency of gas supply even when the pressure in the cylinder varies.

It is equipped with a large diaphragm and a high pressure valve, therefore the sensitivity of regulation guarantees absolute stability and maximum safety thanks to the characteristic overflow system, which intervenes if the pressure exceeds the set value by 0.6 bar predetermined.

The system can be created for all combustible and oxidising gases with the exception of Oxygen and Acetylene, and is available, on request, complete with one or two flow meters, standard or increased preheater, both preheater and flow meter.This instrument introduces some new and important aspects: the gas saving system, which allows a significant reduction in consumption, the integrated pre-heating system and the possibility of powering and regulating up to two welding machines simultaneously thanks to the double flow meter. All these solutions can be integrated into a single reducer, avoiding the need to combine different and expensive independent instruments.

Available in the version with flow meter, double flow meter, pre-heater, increased pre-heater, both accessories

Available with specific treatments for pure and food gases.Nobody / Nobody

Nobody / Standard

Nobody / Increased

Single / Nobody

Single / Standard

Single / Increased

Double / Nobody

Double / Standard

Double / Increased

Pressure reducer mod. VALVOPLAN II

Pressure reducer mod. VALVOPLAN II

-

![]()

![]()

The place taken stands out for itsprecisionin regulation and forease of installation and maintenance.

It is adaptable to a wide range of technical gases and can be connected directly to the gas line or via the interposition of an inlet valve.

Body in solid aluminium / Nobody

Body in solid aluminium / 1

Body in solid aluminium / 2

Body in solid aluminium / 3+

Stainless steel casing / Nobody

Stainless steel casing / 1

Stainless steel casing / 2

Stainless steel casing / 3+

Place taken

Place taken

-

![]()

![]()

The first stage pressure reducer modelSTAR2made from bar stock and its predecessor STAR made from mould, are suitable for use with a large number of technical gases and are built according to standardsEN ISO 2503.

Default Title

Pressure reducer mod. STAR & STAR2

Pressure reducer mod. STAR & STAR2

-

![]()

![]()

This pressure reducer has been totally engineered and made of stainless steel for use with corrosive gases and for applications in which the construction materials become essential to ensure the resistance and durability of the instrument itself.

The adjustment of the output pressure is easily managed thanks to a nylon knob, the pair of pressure gauges allows direct control over the adjustment. The overpressure valve ensures safe working.

Available in different versions with or without pressure gauges.Default Title

Pressure reducer for corrosive gases

Pressure reducer for corrosive gases

-

![]()

![]()

The model pressure reducerRBPit is a second stage reducer suitable for high flow rates.

It finds particular use in the laser and food sectors, in those applications in which a constant and important flow of gas is necessary to compensate for particularly demanding processes.

Default Title

Pressure Reducer Mod. RBP

Pressure Reducer Mod. RBP

-

![]()

![]()

Second stage reducer for medium flow rates.

Thanks to the use of new construction techniques, the use of innovative materials and the use of self-regulating gas control systems, the system becomes reliable, flexible and simple to manage.

Available in different versions with or without pressure gauges.Default Title

Pressure Reducer Mod. RP0

Pressure Reducer Mod. RP0

Alarm systems

In order to prevent critical emergency situations related to food safety, providing timely reports of anomalies in production processes.

Pulmonation systems

They maintain the stability of gas mixtures during transportation and use in food processes, ensuring the highest quality of the final product.

Analysis and Detection Systems

They monitor and control the composition and quality of the gases used in food processes, ensuring regulatory compliance and high quality standards.

Construction of the systems

Cryotek Eng provides customized solutions, from design to installation of food systems, respecting the customer's specific needs and current regulations.

Maintenance

Cryotek Eng offers constant support to ensure the correct functioning of food systems over time, maximizing the efficiency and life of the system.