- ACCESSORIES

- ANALYZERS

- DECOMPRESSION SYSTEMS

- FLOWMETERS

- GENERATORS

- MIXERS

- PRE-HEATING SYSTEMS

- PRESSURE REDUCERS

- SECURITY SYSTEMS

- SPECIAL SYSTEMS AND INSTALLATIONS

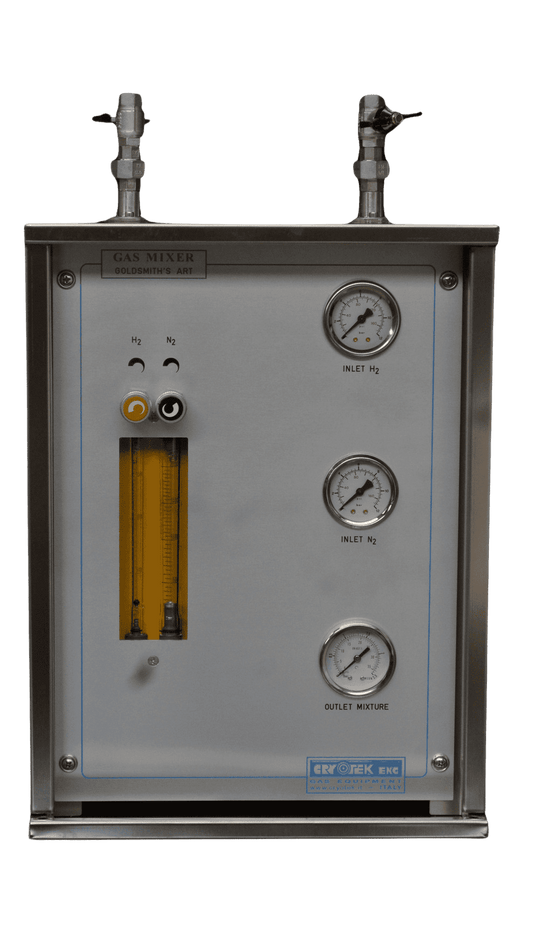

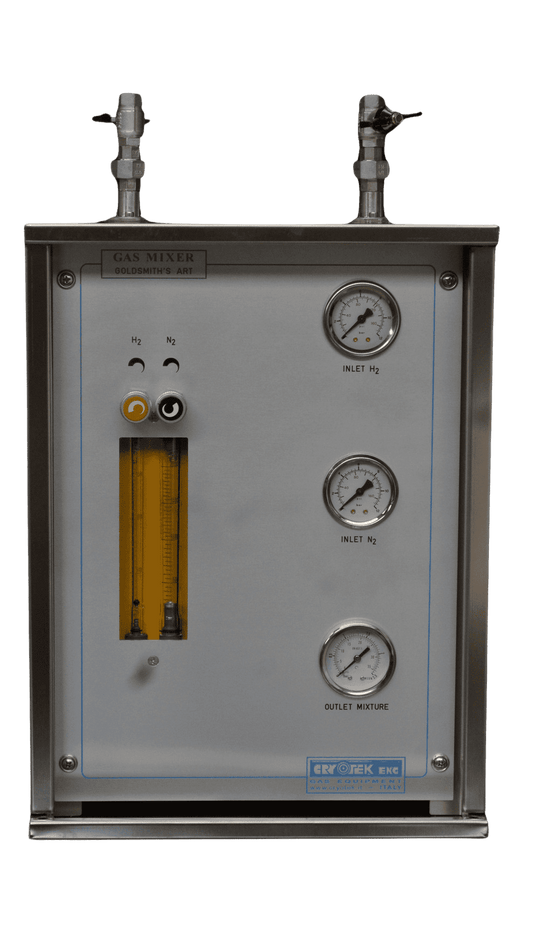

- MIXING SYSTEM MOD. GOLDMIXER

- MIXING SYSTEM MOD. IVA/N – FOOD SECTOR

- MIXING SYSTEM MOD. M04D

- VARIABLE AREA MIXING SYSTEM MOD. IV GOLD SECTOR

- MIXING SYSTEM MOD. IVA – FOOD SECTOR

- LINE MIXING SYSTEM

- MICROMIXER

- MIXING SYSTEM MOD. EASY MIXER

- MIXING SYSTEM MOD. M101S

- MIXING SYSTEM MOD. M20 TOTAL VISION

- MIXING SYSTEM MOD. M20 ARTIC

- MIXING SYSTEM MOD. M04S

- MIXING SYSTEM FOR PRESET MIXTURES

Roboflow Total Control – Electronic Mixer

Description

Description

Thanks to continuous research studies and many years of development and testing, our Roboflow Total Control is now ready and available.

Roboflow Total Control is the most innovative mixing system from Cryotek Eng, i.e. the perfect combination of flexibility, reliability and performance.

The new gas mixing system is an improvement of the previous Cryotek Eng electronic mixing system, a version designed to ensure the highest precision in all operational functions.

Ready to be configured for a wide range of gases, Roboflow Total Control is the most flexible and convenient automatic tool for managing and mixing gases.

The instrument allows you to use and control one or more gases supplied and therefore allows total control of production costs.

It is used in the most varied fields of application such as: welding, heat treatments, food, goldsmithing, clean rooms, advanced electronics and research. Sectors in which digital management of the entire process must also be added to the precision of the mixture strength.

Default Title

TECHNICAL FEATURES

TECHNICAL FEATURES

| Maximum inlet pressure | 15 bar |

| Maximum outlet pressure | 2 bar |

| Inlet connections | 1/4” GF |

| Output connections | 1/4” GF |

| Power supply | 220V |

Contact us

OF THE SAME CATEGORY

-

![]()

![]()

Cryotek Eng, to respond to the growing needs of the goldsmith sector, has studied a new line of mixing systems. The GoldMixer System is an easy-to-install mixer with the advantage of adapting to every production process.

Assembled inside a small frame and made entirely of aluminium, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out thanks to borosilicate glass flowmeters , equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.

The aluminum front synoptic allows for intuitive and easy reading; capable of resisting wear, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies. The synoptic machined in aluminium, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

Absolute precision and high quality are guaranteed by the use of the most advanced technologies.

Default Title

Mixing system MOD. GoldMixer

Mixing system MOD. GoldMixer

-

![]()

![]()

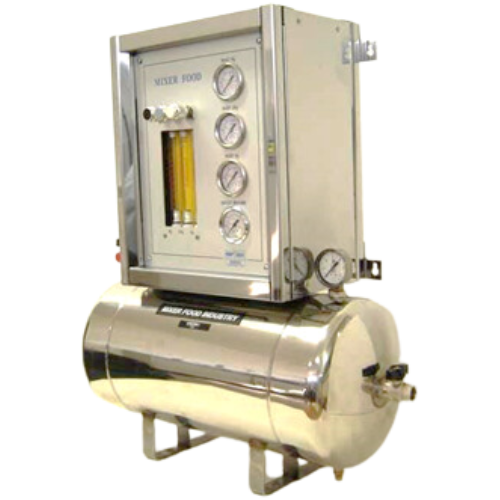

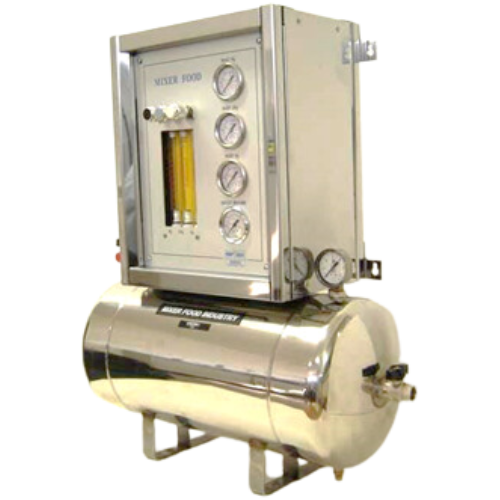

The binary mixer* produced by us to meet the growing needs of the food industry has the advantage of adapting to every production process.

- Assembled inside a small frame, it is extremely light and resistant to all environmental conditions.

- The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters , equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

- Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.**

- The incoming lines are complete with a 60μ filtration system, balanced control piloted pressure reducing valves and one-way valves designed to avoid any pollution of the lines.

- A pilot reducer complete with analogue display placed on the front allows immediate and precise setting of the pressure of the outlet mixture.

- The front synoptic, available in both aluminum and plexiglass, allows for intuitive and easy reading; capable of resisting deterioration, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies.

- The synoptic machined in aluminum, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

* Possibility of ternary version.

**Optional insertion of remote end-of-gas alarms, acoustic, luminous or direct to PLC.Default Title

Mixing System Mod. IVA/N – Food Sector

Mixing System Mod. IVA/N – Food Sector

-

![]()

![]()

The mixer mod. M04D is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization throughout the entire production.

It has the possibility of setting up to four mixtures through a series of micrometric valves which will perform the task of calibrating the flow on each individual line, thus generating a mixture with an accurately defined title.

The user has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system with visual alarm, the possibility of also having control over the stability of the outgoing mixture.

The system is equipped with digital input pressure signals to control the pressures and levels of gas autonomy in the racks and calibrated sockets designed to guarantee correct homogenization of the gas flows which allow the direct analysis of the individual mixtures with special analysers.

Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil & Gas applications.*Available in the version with integrated analysis and blocking system

Default Title

Mixing System Mod. M04D

Mixing System Mod. M04D

-

![]()

![]()

The Cryotek Eng variable area mixer is able to offer from two to four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the organization of the process throughout the production.

It allows you to set up to four mixtures, via a series of micrometric valves, which ensure flow calibration on each individual line, guaranteeing a mixture with a defined and accurate title.

This instrument offers the operator the possibility of having direct control over the strength of the mixture produced and , through a flow control system, also over the stability of the output mixture.

* Available with integrated alarm, blanketing and/or line blocking systems.Default Title

Variable area mixing system Mod. IV gold sector

Variable area mixing system Mod. IV gold sector

-

![]()

![]()

The binary* food mixer produced by us is entirely adaptable to any mixture and gas necessary for the process.

Assembled inside a small frame, made entirely of stainless steel, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters, equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.

Our flow meters, combined with the Venturi system, guarantee precise and continuous control of the mixture by the operator.**

The incoming lines are complete with a 60μ filtration system, balanced control piloted pressure reducing valves and one-way valves designed to avoid any pollution of the lines. A pilot reducer complete with analogue display placed on the front allows immediate and precise setting of the pressure of the outlet mixture.

The aluminum front synoptic allows for intuitive and easy reading; capable of resisting deterioration, it guarantees protection of the instrumentation from atmospheric agents or foreign bodies. The synoptic machined in aluminum, in addition to giving a professional appearance to the equipment, can be customized with your official logo.

* Possibility of ternary version.

**Optional insertion of remote end-of-gas alarms, acoustic, luminous or direct to PLC.

Available with different integrated accessories, including end-of-gas alarm systems, line blocking systems, detection systems, blanketing systems.Default Title

Mixing System Mod. IVA – Food Sector

Mixing System Mod. IVA – Food Sector

-

![]()

![]()

Line mixing system patented and engineered by Cryotek Eng, a device suitable for applications in particularly demanding manufacturing processes, where it is essential to have an instrument capable of producing mixtures in percentages from 0 to 100% on each fluid.

Thanks to the use of highly reliable materials and an innovative construction concept, the instrument is able to cope with the most demanding situations, with precision and consistency.Default Title

Line mixing system

Line mixing system

-

![]()

![]()

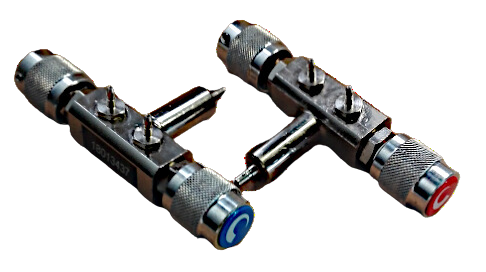

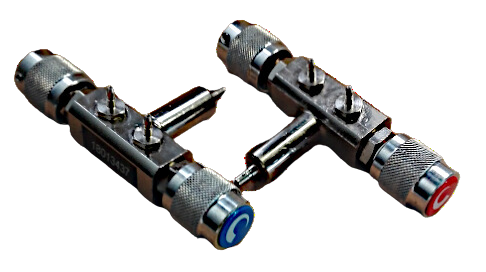

The Cryotek Eng micromixer is a compact and easy to use tool for gold and metal processing.

It is made of chromed brass, and is extremely light and resistant to all environmental conditions. Designed to be easily repaired. It is mainly used for gases such as hydrogen and oxygen, and is equipped with two micrometric valves that allow you to adjust the mixture strength.Default Title

Micromixer

Micromixer

-

![]()

![]()

Compact mixing system, suitable for small flow rates and suitable for the goldsmith, industrial, chemical and food sectors.

The maximum flow regulation is entrusted to direct reading analog systems, based on the Pitot system designed, built and calibrated in our workshops since 1960.

The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.

The pressure regulators located inside the instrument are directly spring operated. If necessary, one-way valves can be supplied.

The device is housed inside a completely sealed stainless steel case, to avoid tampering by unauthorized personnel.

Thanks to its characteristics, the equipment is the result of an excellent combination of cost-effectiveness and product functionality.

Available with specific treatments for pure and food gasesDefault Title

Mixing System Mod. EASY MIXER

Mixing System Mod. EASY MIXER

-

![]()

![]()

The M101S S is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization with the possibility of setting up to four mixtures.

Complete with built-in preheating systems for each single line, 30°C thermostats, exclusion buttons, settable overpressure valves, reading socket for each single line and illuminated panel to allow viewing in low light.

The reading of the flow rates will take place with direct reading analogue systems, based on the Pitot system, designed, built and calibrated specifically for welding systems with large productions.

The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M101S

Mixing System Mod. M101S

-

![]()

Binary mixing system for welding, with 2 separate mix delivery ways.

Binary mixing system for welding, with 2 separate mix delivery ways.![]()

Thanks to the total separation of the 2 lines, each mixture can be individually set in terms of strength and pressure.

The M20 Total Vision mixing system also allows continuous control of the mixture, thanks to an integrated synoptic analysis system.

The digital flow meters placed downstream of the flow meters are capable, like the analyzer, of providing a remotely controllable and recordable signal of the flow rate and quantity values of the individual gases.

The entire system is placed inside a marine stainless steel frame equipped with an opening door and inspection window.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M20 Total Vision

Mixing System Mod. M20 Total Vision

-

![]()

![]()

Binary mixing system for welding, with 2 separate mix delivery ways. Thanks to the total separation of the 2 lines, each mixture can be individually set in terms of strength and pressure, acting on the relevant flow meters and pressure reducers. The system is completed with integrated thermal conditioning and increased gas preheating systems, so as to allow its use at extremely low temperatures.

The entire system is placed inside a marine stainless steel frame equipped with an opening door and inspection window.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M20 ARTIC

Mixing System Mod. M20 ARTIC

-

![]()

![]()

Thanks to new construction techniques, the use of innovative materials and the use of gas control systems, the system becomes reliable, flexible and simple to manage.

The possible advantage is evident.

The M04S mixer is able to offer four autonomous mixers at low costs, in small spaces and in a single frame, thus optimizing the process organization throughout the entire production. It has the possibility of setting up to four mixtures through a series of micrometric valves which will perform the task of calibrating the flow on each individual line, thus generating a mixture with an accurately defined title.

The reading of the flow rates will take place with direct reading analogue systems, based on the Pitot system. Designed, built and calibrated specifically for welding systems with large productions. The user thus has the possibility of obtaining direct control over the strength of the mixture produced and, through a flow control system, also having control over the stability of the outgoing mixture.

Thanks to the tempered glass door with security key, it will be protected from any external tampering by unauthorized personnel.

The system is particularly suitable for Oil&Gas applications.Default Title

Mixing System Mod. M04S

Mixing System Mod. M04S

-

![]()

![]()

The binary or ternary food mixer produced by us is entirely adaptable to any mixture and gas necessary for the process. Assembled inside a small frame, made entirely of stainless steel, it is extremely light and resistant to all environmental conditions.

The measurement of the gases composing the mixture is carried out using borosilicate glass flowmeters, equipped with micrometric taps, produced and calibrated with precision entirely in our workshops.The peculiarity of this tool is that it can have from 3 to 10 pre-set blends with titles that can be customized and reset in a simple and intuitive way directly on site by the customer. In this way the end customer is guaranteed:

• A high-performance product in terms of applications (with the same tool it is possible to package different types of products with different mixtures)

• Greater protection of know-how and set blends.

• An absolute reduction in error when changing the mixture, as the mixture is no longer adjusted through the micrometric valves but by simply moving the knob.

Available with different integrated accessories, including end-of-gas alarm systems, line blocking systems, detection systems, blanketing systems.Default Title

MIXING SYSTEM FOR PRESET MIXTURES

MIXING SYSTEM FOR PRESET MIXTURES