Propane Decompression System - Mod. D117

Description

Description

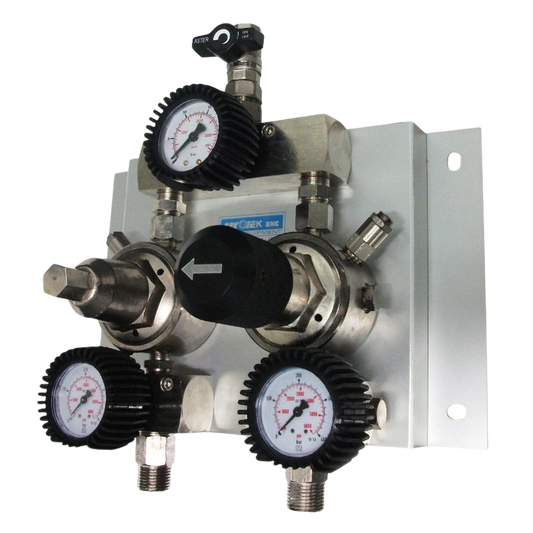

At the inlet we find the main valve and the filter, inside we find a 2nd stage RBP model reducer, capable of reaching a flow rate of 40 Nm3/h complete with adjustment screw accessible from the outside, pressure gauge and non-return flame valve.

Through the transparent pmma window it is possible to check the pressure gauge without the need to open the door.

At the outlet there is a reel equipped with 15 m of 8x15 mm orange rubber hose to which the torch for the actual

usage. The components of the D117 are also available individually:

D47 – Complete decompression unit.

Reel with 15 m of 8×15 mm rubber hose.

The system is particularly suitable for Oil & Gas applications.

Default Title

TECHNICAL FEATURES

TECHNICAL FEATURES

| Maximum inlet pressure | 15 bar |

| Maximum outlet pressure | 4 bar |

| Inlet connections | 3/8″ Gas male left |

| Outlet connections | 3/8″ Gas female left |

Contact us

OF THE SAME CATEGORY

-

![]()

![]()

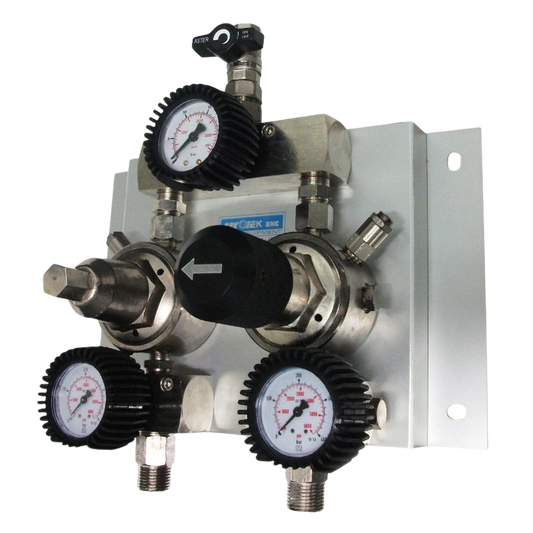

The semi-automatic exchange panel allows the connection of two incoming high pressure gas cylinders, regulating the pressure and introducing the gas into the low pressure line.

The conception of the exchange system allows for a system capable of automatically exchanging the incoming line, in the event of gas running out, with the secondary line already connected to the panel. Once the exchange has taken place, the operator who will replace the first gas source will rearm the automatic exchange and the operation is repeated.

Thanks to non-return valves and particular technical measures, the replacement of terminated sources can be carried out in complete safety.

Equipped with two input pressure gauges and one output pressure gauge for continuous pressure monitoring, overpressure valves placed directly on the reducer body and an output ball valve which allows simple disconnection from the line allowing for easy maintenance.Default Title

Automatic exchange decompression system

Automatic exchange decompression system

-

![]()

Single stage decompression system mod. Easyboard Star 2. The visible first stage decompression unit is equipped with two inlets with anti-transfer valves, thanks to which it is possible to replace the single source with the active panel. The system is completed by two pressure gauges, high and low pressure, and an outlet ball valve. Additionally, a pressure switch is available for remote control of the pressure in the high pressure chamber.

Single stage decompression system mod. Easyboard Star 2. The visible first stage decompression unit is equipped with two inlets with anti-transfer valves, thanks to which it is possible to replace the single source with the active panel. The system is completed by two pressure gauges, high and low pressure, and an outlet ball valve. Additionally, a pressure switch is available for remote control of the pressure in the high pressure chamber.![]()

The outlet pressure adjustment is easily adjustable thanks to a nylon knob, the pair of pressure gauges allows direct control over the adjustment. The overpressure valve ensures safe working.

Able to handle a wide range of gases: combustible, oxidising and inert. Thanks to the use of new construction techniques, the use of innovative materials and the use of self-regulating gas control systems, these instruments are reliable, flexible and simple to manage.

On request we produce versions for pure, hyperpure, medical and food gases.

Depending on the required output pressure, it can be equipped with a diaphragm (up to 10 bar) or with a piston system (up to 60 bar).

Available for mixes and with international bindings.Default Title

EASYBORD Decompression System

EASYBORD Decompression System

-

![]()

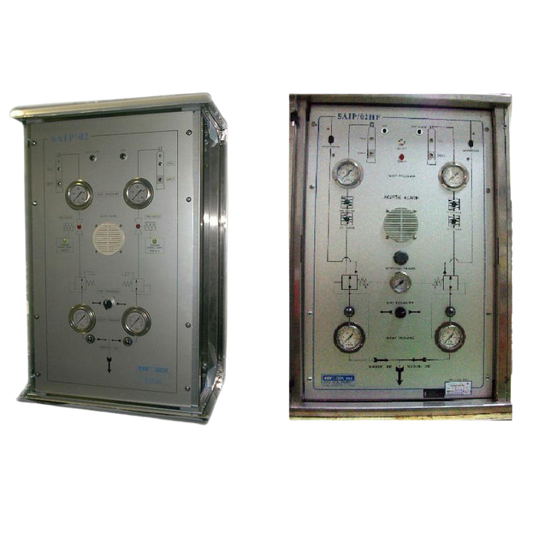

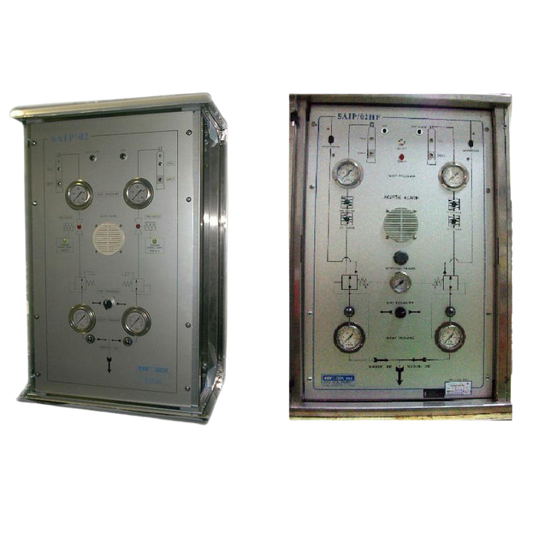

The D02 / D02HF decompression station is a complete gas reduction and control station that does not require any additional equipment.

The D02 / D02HF decompression station is a complete gas reduction and control station that does not require any additional equipment.![]()

The power plant is in fact already equipped with an inlet filtration system, first stage reducers and an integrated differential system capable of managing inlet pressures of up to 200 bar and outlet pressures of up to 10 bar. The electronic pressure transducers with which it is equipped are interfaced with alarm systems capable of warning when the cylinders are in reserve.

The control unit is completed with an automatic exchange system, capable of automatically switching to the full cylinder once the cylinder in process has entered reserve. The integrated alarms cannot be silenced except by replacing the cylinders and restoring the pressure initially set via the selector located on the front panel of the panel. The system is equipped with an interface for connection to an external electric alarm control unit.

The use of essential graphics and the panel-front installation of all the display systems make use and pressure calibration simple and intuitive.

Thanks to the operating principle of the automatic exchange system, it will no longer be necessary to stop production to change the cylinders.

The system is particularly suitable for Oil&Gas applications.Default Title

D02HF Decompression System

D02HF Decompression System

-

![]()

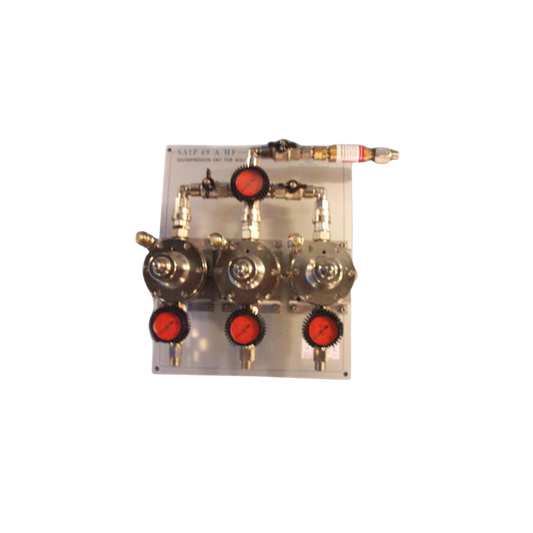

The D49 HF first stage decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting the production.

The D49 HF first stage decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting the production.![]()

Each inlet is equipped with an upstream pressure gauge and a dedicated reducer capable of supplying up to 50 Nm3/h at 12 bar.

The inlet lines then converge into a single outlet equipped with a 1″ non-return flame valve, a pressure gauge to monitor the outlet pressure and a main system supply valve.

The system is particularly suitable for Oil&Gas applications.Default Title

Decompression System Mod. D49 O-HF

Decompression System Mod. D49 O-HF

-

![]()

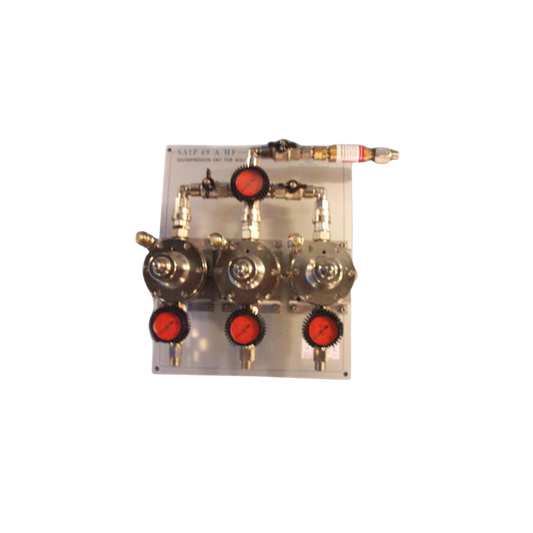

The D49 A HF first stage acetylene decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting production.

The D49 A HF first stage acetylene decompression panel allows the simultaneous connection of three gas sources, such as racks of cylinders or high pressure lines, allowing selective use of the same in order to make up for the possible exhaustion of one of the three without affecting production.![]()

Each inlet is equipped with an upstream pressure gauge and a dedicated RBP reducer capable of providing up to 15 Nm3/h at 1.5 bar.

The inlet lines then converge into a single outlet equipped with a 1″ flame arrestor valve, a pressure gauge to monitor the outlet pressure and a main system supply valve. The system is particularly suited to Oil&Gas applications.Default Title

Decompression System Mod. D49 A-HF

Decompression System Mod. D49 A-HF